George W. Hart

STEAM is a sculpture that I designed to

be assembled by a group of students at Brown

University. It is made of sixty laser-cut birch

plywood components and is about thirty inches in

diameter. The term STEAM stands for Science,

Technology, Engineering, Art, and Mathematics, all of which

are involved in the design of the sculpture.

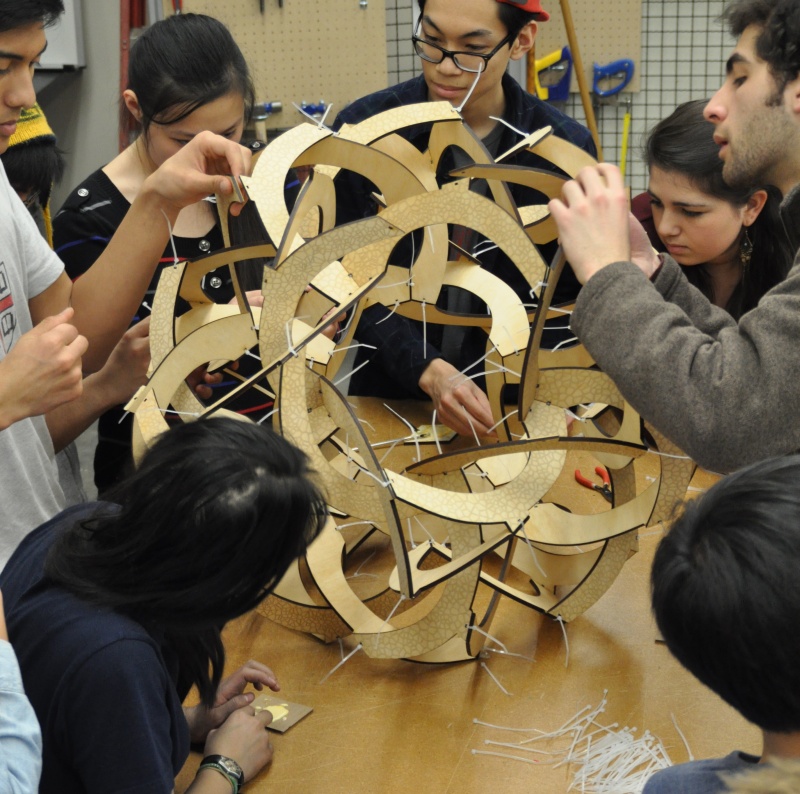

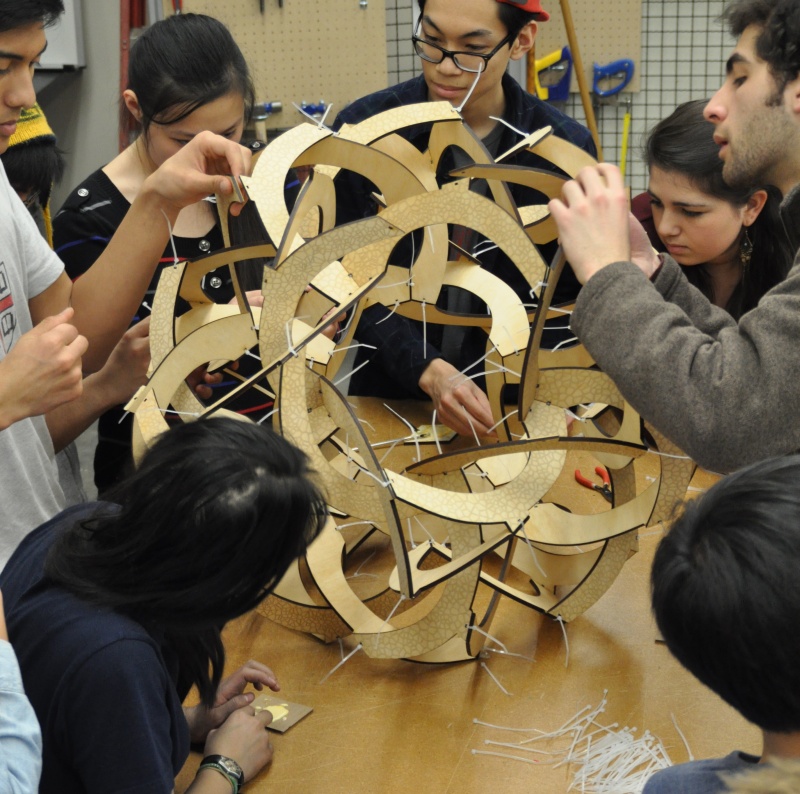

Next, the first five modules are assembled together into a

larger structure. We are working in the air, with five

people holding the modules and five others standing between

them, making the connections.

I decorated the pieces with randomly generated laser-etched

Voronoi patterns. Each part has four small rectangular

holes where it joins to four neighbors with cable

ties. The mating edges are beveled, so there is some

face-to-face contact area where the glue is applied. They

are finished with two coats of tung oil.

Using both glue and cable ties makes for a very rigid

structure yet it can be built fairly quickly with a group of

people working in parallel. It is intricate but highly

regular, so the same types of connections are made all

around in many places. The cable ties hold the parts

together while the glue is drying and adapt automatically to

the angles between the planes.

After the first ten modules are connected together, we can

turn it over and rest it on the end of a work bench.

It is half complete at this point, but still tricky to

finish.

Many people can address it from all sides as they figure out

where to place additional modules. Each joint is glued

as the structure grows. Because of the many overs and

unders, it is a challenging 3D jig-saw puzzle, even though

all the parts are the same shape.

When all the parts are in place, we used wire clippers to cut the protruding ends of the cable ties, leaving a nicely finished appearance. Again, it has to sit for a while for the glue to dry.

The result is very rigid, with a light, open feeling,

simultaneously geometric and organic. When seen in

person, many people observe its inner and outer layers and

think at first that it is two disconnected structures.

But because the layers connect alternately in cycles of five

(and five is an odd number) a little study shows that it is

all one connected component.

Later, the building folks hung it up high in the entryway of the Barus-Holley Engineering and Physics Building.

Thank you to all the students who participated in the assembly event, especially Lukas Winklerprins, who took care of many arrangements. Thank you also to Elizabeth Love, who took many of the above photos.

Here is the start of the construction,

on the afternoon of March 6, 2014. We're working

in the Brown

Design Workshop. Three wooden components at

a time are joined together to make twenty spiral

modules. They are held together with both wood

glue and cable ties. Then we put them aside for a

while to allow the glue to dry.

When all the parts are in place, we used wire clippers to cut the protruding ends of the cable ties, leaving a nicely finished appearance. Again, it has to sit for a while for the glue to dry.

Later, the building folks hung it up high in the entryway of the Barus-Holley Engineering and Physics Building.

If you're ever in Providence, RI, go

visit it and try to make sense of its unique

structure. I hope you enjoy it!

Watch a video of the construction to get a better sense of the design.

Watch a video of the construction to get a better sense of the design.

Thank you to all the students who participated in the assembly event, especially Lukas Winklerprins, who took care of many arrangements. Thank you also to Elizabeth Love, who took many of the above photos.