Here's a big construction I made

with a group of students and faculty at Albion College in

Michigan. It recycles plastic campaign signs that weren't

needed anymore on the day after the election. There are

sixty components and each looks vaguely like a running man.

The first step was to make a master

template and then trace it on stacks of signs. These signs

are 18 inches by 24 inches, so the template is scaled to just

fit in that area. If you want to make a copy of this

design, start by printing out the

template

(pdf version)

at the appropriate scale for your material.

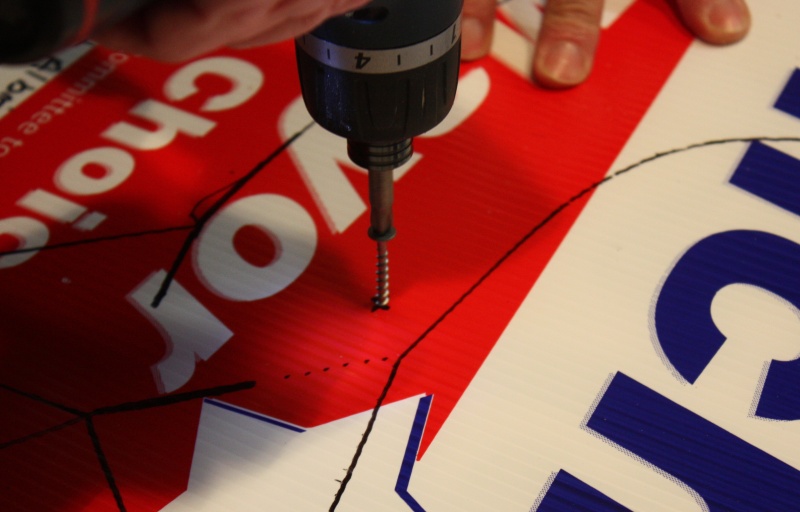

We made stacks of nine sign boards and held them together with

sheet-rock screws. This allowed cutting nine at a time in

one operation.

We started by working up in the air, holding the modules in

their relative positions and making foot connections. We

first did a cycle of five modules, then another group of five

around those.

A band saw easily cuts this

corrugated plastic. For the slots, you need to cut out

a width roughly equal to the thickness of the

material.

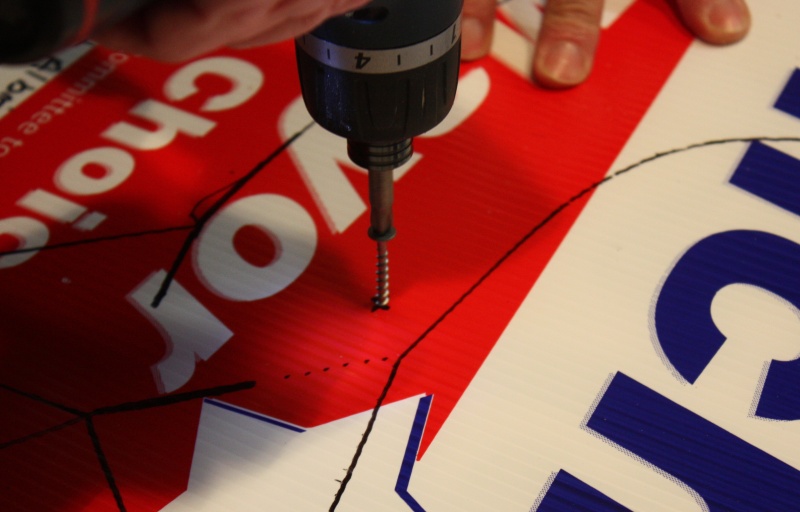

Two holes are drilled in the back feet. Cable ties will later go through the holes to hold the parts together.

Two holes are drilled in the back feet. Cable ties will later go through the holes to hold the parts together.

At the assembly event, we

started by making modules of three parts. The slots at

the head join in a cycle, so one ear needs to be bent to

make the third connection. But it straightens out

nicely and can't slide apart.

On my laptop, I brought along a

computer model of the final result that we could use as a

guide to assembly. Twenty modules are arranged more or

less like an icosahedron. The feet meet in groups of six and

the connection is hidden under another module, so it is

tricky to visualize how everything interweaves.

Looking up from below at the

first five modules shows how they form a pentagonal

opening. When complete, there will be twelve of these

openings. The "Twenty Twelve" in the title is the

number of modules and openings (and also the year).

Here's what the foot

connections look like. Each front foot mates with a back

foot, and the three back feet join like the corner of a

cube. It is all held together with three cable ties

that go through holes in two adjacent feet. The

connection is tricky because all this sits in the basement

of another module, which gets in the way when you try to

access the holes.

With ten modules together, we

turned it over and sat it on the rug. The assembly

algorithm is just to keep adding more modules to the growing

structure.

All the slots fit with no

problems, but reaching inside to thread the cable ties

through the holes wasn't easy. All together, it took

about two and a half hours in the shop to make the parts and

then an hour and ten minutes for the assembly.

The result is strong enough

to hang from one point so it spins slowly with the air

currents. There's a nice view from below. To

get a better understanding of the design, watch the assembly video.

Thank you very much everyone who

participated, including Andrew French for providing the signs

and Ron Fryxell for use of his shop, with a special thank you

to Dave Reimann

for inviting me and taking these pictures.