This

is a webbified version of a paper in the

Proceedings

of

Art

+ Math = X International Conference in

honor of Michele Emmer on his 60th Birthday

Spaghetti Code: A Sculpture Barnraising

Computer Science Department

Stony Brook University

Stony

Abstract

A two-meter diameter metal

sculpture was assembled by a group of two hundred students, faculty,

and staff

at

1. Design

I construct geometric sculpture of various

materials

and like to engage groups of helpers in “sculpture barn raisings” [1-4]. Spaghetti

Code, shown in Figure 1, is my

latest example. The term Spaghetti Code

is computer science jargon for a poorly organized program, but the

sculpture is actually highly organized.

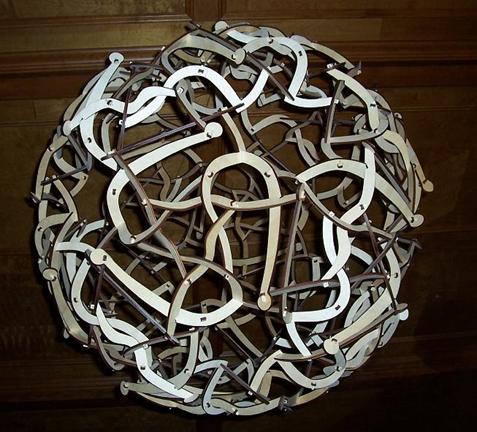

Figure 1:

Spaghetti Code, aluminum, 2

meter diameter.

Spaghetti

Code is constructed of 180

laser-cut, flat, aluminum parts. The form was carefully optimized over

several

months both for its aesthetics and to allow rapid, secure assembly.

When

designing sculpture to be constructed from rigid parts, the connections

are a

difficult issue that must be thought out carefully. My solution in this

case

was 300 simple mortise and tenon joints, locked with stainless steel

cotter pins.

A major difficulty with this approach is that, because of the nature of

laser-cutting, both the mortise (a

rectangular slot) and the

hole in the tenon for the locking pin must be at 90 degrees to the

material.

Consequently, these joints require mating parts to lie in orthogonal

planes. It

would be easy to design a cube or rectangular box under this

constraint, but I

puzzled quite a while about how to make an intricate yet well-connected

form

with icosahedral symmetry using only 90-degree connections.

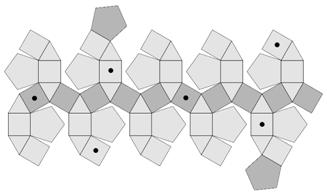

Figure 2: Rhombicosidodecahedron (RID) and its net.

To understand the many 90-degree angles in Spaghetti Code, it may help to begin with the rhomb-icosidodecahedron (RID) of Figure 2. This well-known Archimedean solid comprises 12 pentagons, 20 triangles, and 30 squares. It is not obvious that many pairs of faces lie in planes that intersect each other at 90 degrees. The unfolded net of the RID in Figure 2 illustrates this by shading two opposite pentagons, positioned as a North and South pole, and an “equator” of ten squares. The equatorial squares are halfway between the poles, so their planes lie at 90 degrees to the shaded pentagons’ planes. Because of the symmetry of this polyhedron, we could choose among six different pairs of pentagons to be the poles, each defining an equator of squares. This provides 120 pairs of orthogonal planes. There are also many 90-degree relationships between planes of two square faces. A careful study of the RID shows that the six squares marked with a dot in the net lie in the face planes of a cube, so provide twelve orthogonal pairs. There are five cubes among the 30 squares, providing in total 60 such pairs of orthogonal planes.

To take advantage of these 180 orthogonal plane pairs, the design of Spaghetti Code has 60 components in the twelve planes of the pentagons of one RID (five per pentagon) and has 120 components in the thirty planes of the squares of a larger concentric parallel RID (four per square). Selecting planes from two sizes of RIDs allows extra design freedom, yet scaling a set of planes radially inward or outward is only a translation so neither destroys the symmetry nor changes the 90-degree angle between planes. A total of 300 connections was achieved by having two pairs of parts join at some of the pairs of planes.

To

develop

the detailed form and arrange for the components to pass around others

that lie

in non-orthogonal planes, I used the software of [2]. This software

allows the

visualization and editing of symmetric sculpture, and outputs geometric

description files in formats suitable for laser-cutting and solid

freeform

fabrication. The parts were fabricated at a commercial laser-cutting

service

bureau from 0.1-inch thick aluminum (6061-T6 alloy) and given a surface

brushing on the outer side, which creates a gleaming visual effect.

Preparation

also included deburring the parts and

drilling holes

in five of them for suspending from chains. Before the assembly, I was

able to promote

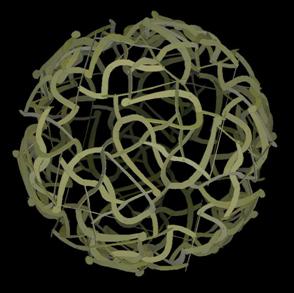

the event with computer renderings such as Figure 3 and a small

physical model.

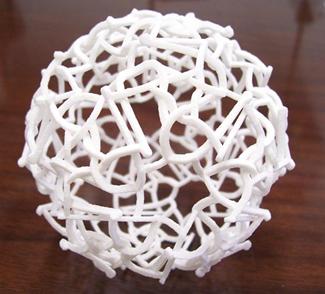

The solid freeform fabrication model, made of nylon by selective laser

sintering, is shown in Figure 4.

Figure 3: Computer rendering.

Figure 4: Laser-sintered nylon model, 3 inches.

As

a final

preparation step, I laser-cut parts for a half-scale version in

quarter-inch Baltic

birch plywood. This allowed me to test the assembly sequence, confirm

the five

suspension points, and verify that I made no gross miscalculations,

before

committing to the expense of laser cutting the metal parts. Figure 5

shows the

assembled wooden version. Its tenons are locked with 300 small wooden

wedges.

Figure 5:

Wood version, 1

meter

diameter.

2. Barn

Raising

The

Figure 6: Initial step of forming triangles.

Figure 7: Completed nine-part module.

The

nine-piece units each have a 3-fold axis of symmetry and correspond in

the

overall structure to one triangle of an icosahedron. Using a temporary

suspension

point in easy reach near the ground, we started assembling the units

together. Figure

8 shows a point where the top five modules are assembled to form a dome

and the

next layer is being added. Again, some intricate weaving is required to

position

the parts properly, but I was able to direct from the center of the

structure

while groups of students worked around me. Figure 9

shows the insertion of cotter pins and gives a view of the mortise and

tenon

joints.

Figure 8: Five modules form a dome.

Figure 9: Inserting cotter pins.

The

adding and

locking of modules continued until its icosahedral form was complete.

Total

assembly time was under two hours. We easily hauled its 80 pounds up to

a hook

that had previously been installed in the ceiling to hold it. Figure 10

shows the

view looking up along a 5-fold axis from directly below.

Figure 10: Completed sculpture, viewed from directly below.

3. Conclusions

Spaghetti Code now hangs in the computer

science building lobby at

References

[1] G. Hart,

"The Millennium Bookball," Proceedings of Bridges

2000:

Mathematical Connections in Art, Music and Science, Southwestern

College,

Winfield, Kansas, July 28-30, 2000, and in Visual Mathematics

2(3) 2000,

and at http://www.georgehart.com

[2] G. Hart,

"Sculpture from Symmetrically

Arranged Planar Components", in Meeting Alhambra, (Proceedings of

ISAMA-Bridges 2003, Granada, Spain), Javier Barrallo

et al editors, Univ. of Granada, 2003, pp. 315-322.

[3] G. Hart,

"A Reconstructible

Geometric Sculpture", Proceedings of ISAMA CTI 2004, DePaul

University, June 17-19, 2004, Stephen Luecking

ed.,

pp. 141-143.

[4] G. Hart,

"A Salamander Sculpture Barn

Raising", Proceedings of Bridges 2004: Mathematical Connections in

Art,

Music, and Science, Southwestern College, Winfield, Kansas, July

2004, and

in Visual Mathematics 7, no. 1, 2005.

Acknowledgements: Thank you Arie

Kaufmann for finding funds to cover the materials. Thank you Jim Quinn

for making the SFF model of Figure 4. Thank you Erik and Martin Demaine for

letting me use a laser-cutter at MIT to make the parts for Figure 5. And thank you

especially

to everyone who participated in the assembly!